Oil Tempered Steel

CHEMICAL COMPOSITION - Steel Tempered in Oil and Quenched for Mechanical Springs EN 10270-2

| Chemical composition mass % | |||||||||

| EN | C | Si | Mn | P | S | Cu | Cr | V | |

| DESIG. | STANDARD | % | % | % | max. % | max. % | max. % | % | % |

| FDC | EN 10270-2 | 0.60-0.75 | 0.10-0.35 | 0.50-1.20 | 0.03 | 0.025 | 0.12 | - | - |

| FDSiCr | EN 10270-2 | 0.50-0.60 | 1.20-1.60 | 0.50-0.90 | 0.03 | 0.025 | 0.12 | 0.50-0.80 | - |

| FDSiCrV | EN 10270-2 | 0.50-0.70 | 1.20-1.65 | 0.40-0.90 | 0.03 | 0.025 | 0.12 | 0.50-1.00 | 0.10-0.25 |

| TDSiCr | EN 10270-2 | 0.50-0.60 | 1.20-1.60 | 0.50-0.90 | 0.025 | 0.02 | 0.1 | 0.50-0.80 | - |

| TDSiCrV | EN 10270-2 | 0.50-0.70 | 1.20-1.65 | 0.40-0.90 | 0.02 | 0.02 | 0.1 | 0.50-1.00 | 0.10-0.25 |

| VDSiCr | EN 10270-2 | 0.50-0.60 | 1.20-1.60 | 0.50-0.90 | 0.025 | 0.02 | 0.06 | 0.50-0.80 | - |

| VDSiCrV | EN 10270-2 | 0.50-0.70 | 1.20-1.65 | 0.40-0.90 | 0.02 | 0.02 | 0.06 | 0.50-1.00 | 0.10-0.25 |

Wire rods used for TD and VD, with few impurities present

| Approximate equivalent | ||||

| EN | US (AISI) | Japan (JIS) | CHINESE | |

| DESIG. | STANDARD | ASTM | JIS G3560 | GB / T 18983 |

| FDC | EN 10270-2 | A 229 | SWO-A B | FDC |

| FDSiCr | EN 10270-2 | A 401 | SWOSC-B | FDCrSi |

| FDSiCrV | EN 10270-2 | - | - | - |

| TDSiCr | EN 10270-2 | A 1000-5 Grade A | - | TDCrSi |

| TDSiCrV | EN 10270-2 | 2 A 1000-5 Grade D | - | - |

| VDSiCr | EN 10270-2 | A 877 | SWOSC-V | VDCrSi |

| VDSiCrV | EN 10270-2 | - | - | - |

MECHANICAL PROPERTIES

| Diameter of the wire | Tensile strength Rm (N/mm2) | ||||||

| Nominal value mm | FDC | FDSiCr | FDSiCrV | TDSiCr | TDSiCrV | VDSiCr | VDSiCrV |

| 0.50 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.55 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.60 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.65 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.70 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.75 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.80 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.85 | 1860-2060 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.90 | 1860-2060 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.95 | 1860-2060 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 1.00 | 1860-2060 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 1.05 | 1810-2010 | 2070-2260 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 1.10 | 1810-2010 | 2070-2260 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 1.20 | 1810-2010 | 2070-2260 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 1.30 | 1810-2010 | 2070-2260 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 1.40 | 1790-1970 | 2060-2250 | 2260-2410 | 2060-2210 | 2210-2360 | 2060-2210 | 2210-2360 |

| 1.50 | 1760-1940 | 2040-2220 | 2260-2410 | 2060-2210 | 2210-2360 | 2060-2210 | 2210-2360 |

| 1.60 | 1760-1940 | 2040-2220 | 2260-2410 | 2060-2210 | 2210-2360 | 2060-2210 | 2210-2360 |

| 1.70 | 1730-1890 | 2000-2180 | 2210-2360 | 2010-2160 | 2130-2310 | 2010-2160 | 2130-2310 |

| 1.80 | 1730-1890 | 2000-2180 | 2210-2360 | 2010-2160 | 2130-2310 | 2010-2160 | 2130-2310 |

| 1.90 | 1730-1890 | 2000-2180 | 2210-2360 | 2010-2160 | 2130-2310 | 2010-2160 | 2130-2310 |

| 2.00 | 1730-1890 | 2000-2180 | 2210-2360 | 2010-2160 | 2130-2310 | 2010-2160 | 2130-2310 |

| 2.25 | 1670-1820 | 1970-2140 | 2160-2310 | 1960-2060 | 2100-2250 | 1960-2060 | 2100-2250 |

| 2.50 | 1670-1820 | 1970-2140 | 2160-2310 | 1960-2060 | 2100-2250 | 1960-2060 | 2100-2250 |

| 2.70 | 1640-1790 | 1950-2120 | 2110-2260 | 1910-2010 | 2060-2210 | 1910-2010 | 2060-2210 |

| 3.00 | 1620-1770 | 1930-2100 | 2110-2260 | 1910-2010 | 2060-2210 | 1910-2010 | 2060-2210 |

| 3.20 | 1600-1750 | 1910-2080 | 2110-2260 | 1910-2010 | 2060-2210 | 1910-2010 | 2060-2210 |

| 3.50 | 1580-1730 | 1900-2060 | 2110-2260 | 1910-2010 | 2010-2160 | 1910-2010 | 2010-2160 |

| 4.00 | 1550-1700 | 1870-2030 | 2060-2210 | 1860-1960 | 2010-2160 | 1860-1960 | 2010-2160 |

| 4.20 | 1540-1690 | 1860-2020 | 2060-2210 | 1860-1960 | 1960-2110 | 1860-1960 | 1960-2110 |

| 4.50 | 1520-1670 | 1850-2000 | 2060-2210 | 1860-1960 | 1960-2110 | 1860-1960 | 1960-2110 |

| 4.70 | 1510-1660 | 1840-1990 | 2010-2160 | 1810-1910 | 1960-2111 | 1810-1910 | 1960-2111 |

| 5.00 | 1500-1650 | 1830-1980 | 2010-2160 | 1810-1910 | 1690-2110 | 1810-1910 | 1690-2110 |

| 5.60 | 1470-1620 | 1800-1950 | 2010-2160 | 1810-1910 | 1910-2060 | 1810-1910 | 1910-2060 |

| 6.00 | 1460-1610 | 1780-1930 | 1960-2110 | 1760-1860 | 1910-2060 | 1760-1860 | 1910-2060 |

| 6.50 | 1440-1590 | 1760-1910 | 1960-2110 | 1760-1860 | 1910-2060 | 1760-1860 | 1910-2060 |

| 7.00 | 1430-1580 | 1740-1890 | 1960-2110 | 1710-1810 | 1860-2010 | 1710-1810 | 1860-2010 |

| 7.50 | 1400-1550 | 1710-1860 | 1910-2050 | 1710-1810 | 1680-2010 | 1710-1810 | 1680-2010 |

| 8.00 | 1400-1550 | 1710-1860 | 1910-2050 | 1710-1810 | 1680-2010 | 1710-1810 | 1680-2010 |

| 8.50 | 1380-1530 | 1700-1850 | 1890-2030 | 1670-1770 | 1810-1960 | 1670-1770 | 1810-1960 |

| 9.00 | 1360-1510 | 1660-1810 | 1870-2010 | 1670-1770 | 1810-1960 | 1670-1770 | 1810-1960 |

| 9.50 | 1360-1510 | 1660-1810 | 1870-2010 | 1670-1770 | 1810-1960 | 1670-1770 | 1810-1960 |

| 10.00 | 1360-1510 | 1660-1810 | 1870-2010 | 1670-1770 | 1810-1910 | 1670-1770 | 1810-1960 |

| 11.00 | 1320-1470 | 1620-1770 | 1830-1970 | * | * | * | * |

| 12.00 | 1320-1470 | 1620-1770 | 1830-1970 | * | * | * | * |

| 13.00 | 1280-1430 | 1580-1730 | 1790-1930 | * | * | * | * |

| 14.00 | 1280-1413 | 1580-1730 | 1790-1930 | * | * | * | * |

| 15.00 | 1270-1420 | 1570-1720 | 1780-1920 | * | * | * | * |

| 16.00 | 1250-1400 | 1550-1700 | 1760-1900 | * | * | * | * |

| 17.00 | 1250-1400 | 1550-1700 | 1760-1900 | * | * | * | * |

* Under a commercial agreement.

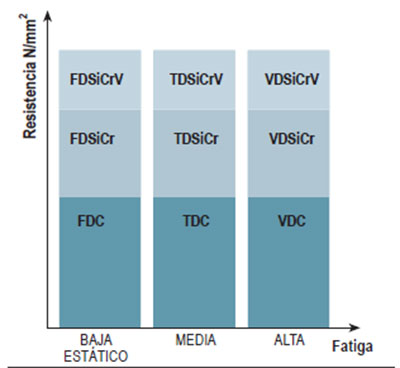

USE OF DIFFERENT TYPES OF WIRE

| TYPE | DESCRIPTION |

| FDC | Suitable for static applications. |

| FDSiCr | |

| FDSiCrV | |

| TDSiCr | Steel wire for springs with medium fatigue levels, such as that required for alloy and non-alloy steel clutch springs. |

| TDSiCrV | |

| VDSiCr | Wire for alloy and non-alloy steel springs for use with severe dynamic stresses, such as springs for valves. |

| VDSiCrV |

Tensile Strength (N/mm2) Vs Fatigue

* SOURCE STANDARD EN 10270-2

| Tensile strength | Static | Medium fatigue | High fatigue |

| Low | FDC | TDC | VDC |

| Medium | FDCrV | TDCrV | VDCrV |

| High | FDSiCr | TDSiCr | VDSiCr |

| Very high | FDSiCrV | TDSiCrV | VDSiCrV |

CONDITIONING

| Nominal value mm. | Inner diameter (approx.) | Outer diameter (approx.) | Weight of the roll |

| 1.40-1.99 | 600 mm. (24'') | 850 mm. | approx. 300 kg. |

| 2.00-2.99 | 900 mm. (36'') | 1100 mm. | 500-1000 kg. |

| 3.00-4.99 | 1200 mm. (48'') | 1400 mm. | 500-1000 kg. |

| 5.00-8.00 | 1500 mm. (60'') | 1800 mm. | 500-1000 kg. |

| 8.00-16.00 | 1800 mm. (72'') | 2050 mm. | 1000-2000 kg. |

The material can be placed on racks and, if so, more than one roll per rack.

The rolls unwind in an ANTI-CLOCKWISE direction.

Diameters below 1.40mm and above 16.0mm on request

Surface quality EN 10270-1

Permissible depth of surface defects

| Type of wire | VD | TD | FD |

| C | 0.005 d | 0.008 d | 0.010 d |

| SiCr, SiCrV | 0.010 d | 0.013 d | 0.015 d |

Permissible surface defects through Foucault current test (Eddy Current Test).

| Nominal diameter d | Maximum depth of the defect a) | |

| mm | VD | TD |

| 2.50 ≤ d ≤ 4.99 | 40 µm | 60 µm |

| 4.99 ≤ d ≤ 5.99 | 50 µm | 60 µm |

| 5.99 ≤ d ≤ 8.00 | 60 µm | 0.01 d |

a) ECT also possible for FD quality and diameters 8mm-16mm under a commercial agreement.

Surface decarburisation

| Type of wire | VD | TD | FD |

| C | 0.005 d | 0.008 d | 0.010 d |

| SiCr, SiCrV | 0.010 d | 0.013 d | 0.015 d |

We are able to supply special qualities and qualities not covered by any standards, under a commercial agreement.

TRIMMING

| FDC | On request |

| FDSiCr | On request |

| FDSiCrV | On request |

| TDSiCr | On request |

| TDSiCrV | On request |

| VDSiCr | <2.5mm on request |

| VDSiCrV | <2.5mm on request |

Diameter tolerances. Permissible deviations according to EN 10270-2

| DIAMETER OF THE WIRE | |

| Nominal value mm | Permissible deviations |

| 0.50 ≤ d < 0.85 | +/- 0.010 |

| 0.85 ≤ d < 1.05 | +/- 0.015 |

| 1.05 ≤ d < 1.70 | +/- 0.020 |

| 1.70 ≤ d < 3.00 | +/- 0.025 |

| 3.00 ≤ d < 4.20 | +/- 0.030 |

| 4.20 ≤ d < 6.00 | +/- 0.035 |

| 6.00 ≤ d < 7.50 | +/- 0.040 |

| 7.50 ≤ d < 9.00 | +/- 0.045 |

| 9.00 ≤ d < 11.00 | +/- 0.050 |

| 11.00 ≤ d < 13.00 | +/- 0.070 |

| 13.00 ≤ d < 16.00 | +/- 0.080 |

| 16.00 ≤ d ≤ 17.00 | +/- 0.090 |

OVALITY

LENGTH TOLERANCES OF THE CUT LENGTHS

| NOMINAL LENGTH | TOLERANCE |

| L < = 1000 mm. | +/- 1 mm. |

| 1000 < L < = 4000 | - 0mm. / +3 mm. |

Thanks to our wire rolling technology we are able to offer our customers the flat wire and square...

Thanks to our wire rolling technology we are able to offer our customers the flat wire and square...