Hard Drawn Steel

CHEMICAL COMPOSITION, MASS % EN 10270-1:2011

| Chemical composition % | |||||||

| Designation | European Standard (EN) | C | Si | Mn | Max. P | Max. S | Max. Cu |

| SL | EN 10270-1 | 0.35 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.035 | 0.035 | 0.20 |

| SM | EN 10270-1 | 0.35 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.035 | 0.035 | 0.20 |

| SH | EN 10270-1 | 0.35 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.035 | 0.035 | 0.20 |

| DM | EN 10270-1 | 0.45 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.020 | 0.025 | 0.12 |

| DH | EN 10270-1 | 0.45 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.020 | 0.025 | 0.12 |

| CLASS II | DIN 17223:1964-1 | values not guaranteed | 0.030 | 0.030 | 0.12 | ||

Note- For diameters ≥ 1.6mm , the product can be supplied using patented or unpatented lead material.

APPROXIMATE EQUIVALENTS

| EUROPEAN | AMERICAN | JAPANESE | CHINESE | ||

| DESIGNATION | EN STANDARD | DIN | ASTM | G-3506 / G3522 | GB / T 4357 |

| SL | EN 10270-1 | CLASS A | A 227 | SWB | SL |

| SM | EN 10270-1 | CLASS B | A 227 | SWC | SM |

| SH | EN 10270-1 | CLASS C | A 228 | SWP-B | SH |

| DM | EN 10270-1 | - | A 227 | - | - |

| DH | EN 10270-1 | CLASS D | A 228 | SWP-B | DH |

| CLASS II | DIN 17223:1964-1 | CLASS II | - | - | - |

APPLICATION

| TYPE | APPLICATION |

| SL | Tension, compression or torsion springs that are chiefly subjected to low static stress. |

| SM | Tension, compression or torsion springs that are subjected to medium-high static stresses or, rarely, dynamic stresses. |

| DM | Tension, compression or torsion springs that are subjected to medium-high dynamic stresses. Also for wire shapes that require severe bending. |

| SH | Tension, compression or torsion springs that are subjected to high static stresses or moderately dynamic stresses. |

| DH | Tension, compression and torsion springs that are mainly submitted to high static strains and to medium levels of dynamic strains. |

| CLASS II | Compression springs, extension springs,and torsion springs for high and dynamic stresses. |

Types of wires for springs. Classed according to EN 10270-1:

| Tensile strength | Static conditions | Dynamic conditions |

| Low | SL | - |

| Medium | SM | DM |

| High | SH | DH |

MECHANICAL PROPERTIES AND QUALITY REQUIREMENTS OF THE SL, SM, DM, SH AND DH STEEL WIRE TYPES EN 10270-1

| Diameter of the wire d | Tensile strength Rm For steel wires of the type | CLASS II (approx.) 1) | Minimum area reduction after Z break for SL, SM, SH, DM and DH wire types | ||||

| Nominal value mm | SL | SM | DM | SH | DH e | ||

| MPa | MPa | MPa | MPa | MPa | % | ||

| d = 0.05 | - | - | - | - | 2800 - 3520 | ||

| 0.05 < d ≤ 0.06 | - | - | - | - | 2800 - 3520 | ||

| 0.06 < d ≤ 0.07 | - | - | - | - | 2800 - 3520 | ||

| 0.07 < d ≤ 0.08 | - | - | - | - | 2800 - 3480 | ||

| 0.08 < d ≤ 0.09 | - | - | - | - | 2800 - 3430 | ||

| 0.09 < d ≤ 0.10 | - | - | - | - | 2800 - 3380 | ||

| 0.10 < d ≤ 0.11 | - | - | - | - | 2800 - 3350 | ||

| 0.11 < d ≤ 0.12 | - | - | - | - | 2800 - 3320 | 2700 - 3090 | |

| 0.12 < d ≤ 0.14 | - | - | - | - | 2800 - 3250 | ||

| 0.14 < d ≤ 0.16 | - | - | - | - | 2800 - 3200 | ||

| 0.16 < d ≤ 0.18 | - | - | - | - | 2800 - 3160 | ||

| 0.18 < d ≤ 0.20 | - | - | - | - | 2800 - 3110 | ||

| 0.20 < d ≤ 0.22 | - | - | - | - | 2770 - 3080 | ||

| 0.22 < d ≤ 0.25 | - | - | - | - | 2770 - 3010 | ||

| 0.25 < d ≤ 0.28 | - | - | - | - | 2680 - 2970 | ||

| 0.28 < d ≤ 0.30 | - | 2370 - 2650 | 2370 - 2650 | 2660 - 2940 | 2660 - 2940 | ||

| 0.30 < d ≤ 0.32 | - | 2350 - 2630 | 2350 - 2630 | 2640 - 2920 | 2640 - 2920 | ||

| 0.32 < d ≤ 0.34 | - | 2330 - 2600 | 2330 - 2600 | 2610 - 2890 | 2610 - 2890 | ||

| 0.34 < d ≤ 0.36 | - | 2310 - 2580 | 2310 - 2580 | 2590 - 2870 | 2590 - 2870 | 2650 - 3040 | |

| 0.36 < d ≤ 0.38 | - | 2290 - 2560 | 2290 - 2560 | 2570 - 2850 | 2570 - 2850 | ||

| 0.38 < d ≤ 0.40 | - | 2270 - 2550 | 2270 - 2550 | 2560 - 2830 | 2560 - 2830 | ||

| 0.40 < d ≤ 0.43 | - | 2250 - 2520 | 2250 - 2520 | 2530 - 2800 | 2530 - 2800 | ||

| 0.43 < d ≤ 0.45 | - | 2240 - 2500 | 2240 - 2500 | 2510 - 2780 | 2510 - 2780 | ||

| 0.45 < d ≤ 0.48 | - | 2220 - 2480 | 2220 - 2480 | 2490 - 2760 | 2490 - 2760 | 2650 - 2940 | |

| 0.48 < d ≤ 0.50 | - | 2200 - 2470 | 2200 - 2470 | 2480 - 2740 | 2480 - 2740 | ||

| 0.50 < d ≤ 0.53 | - | 2180 - 2450 | 2180 - 2450 | 2460 - 2720 | 2460 - 2720 | ||

| 0.53 < d ≤ 0.56 | - | 2170 - 2430 | 2170 - 2430 | 2440 - 2700 | 2440 - 2700 | ||

| 0.56 < d ≤ 0.60 | - | 2140 - 2400 | 2140 - 2400 | 2410 - 2670 | 2410 - 2670 | ||

| 0.60 < d ≤ 0.63 | - | 2130 - 2380 | 2130 - 2380 | 2390 - 2650 | 2390 - 2650 | 2550 - 2840 | |

| 0.63 < d ≤ 0.65 | - | 2120 - 2370 | 2120 - 2370 | 2380 - 2640 | 2380 - 2640 | ||

| 0.65 < d ≤ 0.70 | - | 2090 - 2350 | 2090 - 2350 | 2360 - 2610 | 2360 - 2610 | ||

| 0.70 < d ≤ 0.75 | - | 2070 - 2320 | 2070 - 2320 | 2330 - 2580 | 2330 - 2580 | ||

| 0.75 < d ≤ 0.80 | - | 2050 - 2300 | 2050 - 2300 | 2310 - 2560 | 2310 - 2560 | 40 | |

| 0.80 < d ≤ 0.85 | - | 2030 - 2280 | 2030 - 2280 | 2290 - 2530 | 2290 - 2530 | 2500 - 2800 | 40 |

| 0.85 < d ≤ 0.90 | - | 2010 - 2260 | 2010 - 2260 | 2270 - 2510 | 2270 - 2510 | 40 | |

| 0.90 < d ≤ 0.95 | - | 2000 - 2240 | 2000 - 2240 | 2250 - 2490 | 2250 - 2490 | 40 | |

| 0.95 < d ≤ 1.00 | 1720 - 1970 | 1980 - 2220 | 1980 - 2220 | 2230 - 2470 | 2230 - 2470 | 40 | |

| 1.00 < d ≤ 1.05 | 1710 - 1950 | 1960 - 2200 | 1960 - 2200 | 2210 - 2450 | 2210 - 2450 | 2450 - 2750 | 40 |

| 1.05 < d ≤ 1.10 | 1690 - 1940 | 1950 - 2190 | 1950 - 2190 | 2200 - 2430 | 2200 - 2430 | 40 | |

| 1.10 < d ≤ 1.20 | 1670 - 1910 | 1920 - 2160 | 1920 - 2160 | 2170 - 2400 | 2170 - 2400 | 40 | |

| 1.20 < d ≤ 1.25 | 1660 - 1900 | 1910 - 2140 | 1910 - 2140 | 2150 - 2380 | 2150 - 2380 | 40 | |

| 1.25 < d ≤ 1.30 | 1640 - 1890 | 1900 - 2130 | 1900 - 2130 | 2140 - 2370 | 2140 - 2370 | 2350 - 2650 | 40 |

| 1.30 < d ≤ 1.40 | 1620 - 1860 | 1870 - 2100 | 1870 - 2100 | 2110 - 2340 | 2110 - 2340 | 40 | |

| 1.40 < d ≤ 1.50 | 1600 - 1840 | 1850 - 2080 | 1850 - 2080 | 2090 - 2310 | 2090 - 2310 | 40 | |

| 1.50 < d ≤ 1.60 | 1590 - 1820 | 1830 - 2050 | 1830 - 2050 | 2060 - 2290 | 2060 - 2290 | 2260 - 2500 | 40 |

| 1.60 < d ≤ 1.70 | 1570 - 1800 | 1810 - 2030 | 1810 - 2030 | 2040 - 2260 | 2040 - 2260 | 40 | |

| 1.70 < d ≤ 1.80 | 1550 - 1780 | 1790 - 2010 | 1790 - 2010 | 2020 - 2240 | 2020 - 2240 | 2210 - 2450 | 40 |

| 1.80 < d ≤ 1.90 | 1540 - 1760 | 1770 - 1990 | 1770 - 1990 | 2000 - 2220 | 2000 - 2220 | 40 | |

| 1.90 < d ≤ 2.00 | 1520 - 1750 | 1760 - 1970 | 1760 - 1970 | 1980 - 2200 | 1980 - 2200 | 2110 - 2350 | 40 |

| 2.00 < d ≤ 2.10 | 1510 - 1730 | 1740 - 1960 | 1740 - 1960 | 1970 - 2180 | 1970 - 2180 | 40 | |

| 2.10 < d ≤ 2.25 | 1490 - 1710 | 1720 - 1930 | 1720 - 1930 | 1940 - 2150 | 1940 - 2150 | 40 | |

| 2.25 < d ≤ 2.40 | 1470 - 1690 | 1700 - 1910 | 1700 - 1910 | 1920 - 2130 | 1920 - 2130 | - | 40 |

| 2.40 < d ≤ 2.50 | 1460 - 1680 | 1690 - 1890 | 1690 - 1890 | 1900 - 2110 | 1900 - 2110 | 40 | |

| 2.50 < d ≤ 2.60 | 1450 - 1660 | 1670 - 1880 | 1670 - 1880 | 1890 - 2100 | 1890 - 2100 | 40 | |

| 2.60 < d ≤ 2.80 | 1420 - 1640 | 1650 - 1850 | 1650 - 1850 | 1860 - 2070 | 1860 - 2070 | - | 40 |

| 2.80 < d ≤ 3.00 | 1410 - 1620 | 1630 - 1830 | 1630 - 1830 | 1840 - 2040 | 1840 - 2040 | - | 40 |

| 3.00 < d ≤ 3.20 | 1390 - 1600 | 1610 - 1810 | 1610 - 1810 | 1820 - 2020 | 1820 - 2020 | - | 40 |

| 3.20 < d ≤ 3.40 | 1370 - 1580 | 1590 - 1780 | 1590 - 1780 | 1790 - 1990 | 1790 - 1990 | - | 40 |

| 3.40 < d ≤ 3.60 | 1350 - 1560 | 1570 - 1760 | 1570 - 1760 | 1770 - 1970 | 1770 - 1970 | - | 40 |

| 3.60 < d ≤ 3.80 | 1340 - 1540 | 1550 - 1740 | 1550 - 1740 | 1750 - 1950 | 1750 - 1950 | - | 40 |

| 3.80 < d ≤ 4.00 | 1320 - 1520 | 1530 - 1730 | 1530 - 1730 | 1740 - 1930 | 1740 - 1930 | - | 35 |

| 4.00 < d ≤ 4.25 | 1310 - 1500 | 1510 - 1700 | 1510 - 1700 | 1710 - 1900 | 1710 - 1900 | - | 35 |

| 4.25 < d ≤ 4.50 | 1290 - 1490 | 1500 - 1680 | 1500 - 1680 | 1690 - 1880 | 1690 - 1880 | - | 35 |

| 4.50 < d ≤ 4.75 | 1270 - 1470 | 1480 - 1670 | 1480 - 1670 | 1680 - 1860 | 1680 - 1860 | - | 35 |

| 4.75 < d ≤ 5.00 | 1260 - 1450 | 1460 - 1650 | 1460 - 1650 | 1660 - 1840 | 1660 - 1840 | - | 35 |

| 5.00 < d ≤ 5.30 | 1240 - 1430 | 1440 - 1630 | 1440 - 1630 | 1640 - 1820 | 1640 - 1820 | - | 35 |

| 5.30 < d ≤ 5.60 | 1230 - 1420 | 1430 - 1610 | 1430 - 1610 | 1620 - 1800 | 1620 - 1800 | - | 35 |

| 5.60 < d ≤ 6.00 | 1210 - 1390 | 1400 - 1580 | 1400 - 1580 | 1590 - 1770 | 1590 - 1770 | - | 35 |

| 6.00 < d ≤ 6.30 | 1190 - 1380 | 1390 - 1560 | 1390 - 1560 | 1570 - 1750 | 1570 - 1750 | - | 35 |

| 6.30 < d ≤ 6.50 | 1180 - 1370 | 1380 - 1550 | 1380 - 1550 | 1560 - 1740 | 1560 - 1740 | - | 35 |

| 6.50 < d ≤ 7.00 | 1160 - 1340 | 1350 - 1530 | 1350 - 1530 | 1540 - 1710 | 1540 - 1710 | - | 35 |

| 7.00 < d ≤ 7.50 | 1140 - 1320 | 1330 - 1500 | 1330 - 1500 | 1510 - 1680 | 1510 - 1680 | - | 30 |

| 7.50 < d ≤ 8.00 | 1120 - 1300 | 1310 - 1480 | 1310 - 1480 | 1490 - 1660 | 1490 - 1660 | - | 30 |

| 8.00 < d ≤ 8.50 | 1110 - 1280 | 1290 - 1460 | 1290 - 1460 | 1470 - 1630 | 1470 - 1630 | - | 30 |

| 8.50 < d ≤ 9.00 | 1090 - 1260 | 1270 - 1440 | 1270 - 1440 | 1450 - 1610 | 1450 - 1610 | - | 30 |

| 9.00 < d ≤ 9.50 | 1070 - 1250 | 1260 - 1420 | 1260 - 1420 | 1430 - 1590 | 1430 - 1590 | - | 30 |

| 9.50 < d ≤ 10.00 | 1060 - 1230 | 1240 - 1400 | 1240 - 1400 | 1410 - 1570 | 1410 - 1570 | - | 30 |

| 10.00 < d ≤ 10.50 | - | 1220 - 1380 | 1220 - 1380 | 1390 - 1550 | 1390 - 1550 | - | 30 |

| 10.50 < d ≤ 11.00 | - | 1210 - 1370 | 1210 - 1370 | 1380 - 1530 | 1380 - 1530 | - | 30 |

| 11.00 < d ≤ 12.00 | - | 1180 - 1340 | 1180 - 1340 | 1350 - 1500 | 1350 - 1500 | - | 30 |

| 12.00 < d ≤ 12.50 | - | 1170 - 1320 | 1170 - 1320 | 1130 - 1480 | 1130 - 1480 | - | 28 |

| 12.50 < d ≤ 13.00 | - | 1160 - 1310 | 1160 - 1310 | 1320 - 1470 | 1320 - 1470 | - | 28 |

| 13.00 < d ≤ 14.00 | - | 1130 - 1280 | 1130 - 1280 | 1290 - 1440 | 1290 - 1440 | - | 28 |

| 14.00 < d ≤ 15.00 | - | 1160 - 1260 | 1160 - 1260 | 1270 - 1410 | 1270 - 1410 | - | 28 |

| 15.00 < d ≤ 16.00 | - | 1090 - 1230 | 1090 - 1230 | 1240 - 1390 | 1240 - 1390 | - | 28 |

| 16.00 < d ≤ 17.00 | - | 1070 - 1210 | 1070 - 1210 | 1220 - 1360 | 1220 - 1360 | - | 28 |

| 17.00 < d ≤ 18.00 | - | 1050 - 1190 | 1050 - 1190 | 1200 - 1340 | 1200 - 1340 | - | 28 |

| 18.00 < d ≤ 19.00 | - | 1030 - 1170 | 1030 - 1170 | 1180 - 1320 | 1180 - 1320 | - | 28 |

| 19.00 < d ≤ 20.00 | - | 1020 - 1150 | 1020 - 1150 | 1160 - 1300 | 1160 - 1300 | - | 28 |

1) The values listed in DIN 17223:1964 were given in kg/mm2; the conversion performed is for guidance purposes.

PERMISSIBLE TENSILE STRENGTH RANGE (MPa) IN A SINGLE PACKAGE EN 10270-1:2011

| Nominal diameter d mm | SL, SM, SH | DM, DH |

| d < 0.80 | 150 | 150 |

| 0.80 ≤ d < 1.60 | 120 | 100 |

| 1.60 ≤ d | 120 | 70 |

The requirements are applicable to unit packages in which the mass in kilogrammes is not greater than the value 250 x d (d = wire diameter in mm) or a value of 1000 kg. In the case of coils with a higher mass, appropriate arrangements must be agreed.

Coatings subject to Standards:

| Coating | Description | |

| Phosphated | ph | The wire is treated in a solution so that a layer of phosphated metal forms on its surface. |

| Galvanising | Z | The surface is coated in a layer of zinc. |

| Zinc - Aluminium | ZA | The surface is coated in a layer of Zn 95 / Al 5(%) |

| Reddish | rd | The surface is coated with a thin layer of copper, normally a conversion coating. |

| Coppery | Cu | The surface is coated in a thick (even) layer of copper |

MINIMUM COATING DENSITY REQUIRED OF ZINC OR ZINC/ALUMINIUM EN 10270-1

| Nominal diameter d mm | Minimum coating density a) b) g/m² |

| 0.20 ≤ d < 0.25 | 20 |

| 0.25 ≤ d < 0.40 | 25 |

| 0.40 ≤ d < 0.50 | 30 |

| 0.50 ≤ d < 0.60 | 35 |

| 0.60 ≤ d < 0.70 | 40 |

| 0.70 ≤ d < 0.80 | 45 |

| 0.80 ≤ d < 0.90 | 50 |

| 0.90 ≤ d < 1.00 | 55 |

| 1.00 ≤ d < 1.20 | 60 |

| 1.20 ≤ d < 1.40 | 65 |

| 1.40 ≤ d < 1.65 | 70 |

| 1.65 ≤ d < 1.85 | 75 |

| 1.85 ≤ d < 2.15 | 80 |

| 2.15 ≤ d < 2.50 | 85 |

| 2.50 ≤ d < 2.80 | 95 |

| 2.80 ≤ d < 3.20 | 100 |

| 3.20 ≤ d < 3.80 | 105 |

| 3.80 ≤ d < 10.00 | 110 |

a) The requirements regarding zinc coatings fall within class C in Standard EN 10244-2:2009.

b) If different coating weights are required, priority will be given to the reference coating weights established in Standard En 10244-2 (for example: class D of standard En 10244-2:2009).

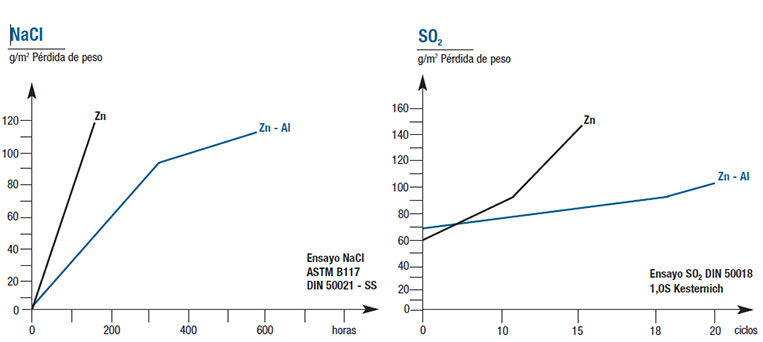

SALT SPRAY TEST

| GALVANISED COATING | Zn - Al COATING | ||

| Exposure time (hours) | Density of Zn (g/m2) | Exposure time (hours) | Density of Zn - Al (g/m2) |

| 36 | 80 | - | - |

| 48 | 90 | 120 | >40 |

| 72 | 105 | 240 | >60 |

| 96 | 125 | 264 | >75 |

| 120 | 165 | 288 | >85 |

| 144 | 195 | 312 | >100 |

| 168 | 220 | 360 | >110 |

| 192 | 240 | 408 | >125 |

Diameter tolerances. Permissible deviations according to EN 10270-1

| Diameter of the wire d | |

| Nominal value mm | Permissible deviations mm |

| 0.05 < d ≤ 0.09 | ± 0.003 |

| 0.09 < d ≤ 0.16 | ± 0.004 |

| 0.16 < d ≤ 0.25 | ± 0.005 |

| 0.25 < d ≤ 0.63 | ± 0.008 |

| 0.63 < d ≤ 0.75 | ± 0.010 |

| 0.75 < d ≤ 1.00 | ± 0.015 |

| 1.00 < d ≤ 1.20 | ± 0.020 |

| 1.20 < d ≤ 1.70 | ± 0.020 |

| 1.70 < d ≤ 2.60 | ± 0.025 |

| 2.60 < d ≤ 4.00 | ± 0.030 |

| 4.00 < d ≤ 5.30 | ± 0.035 |

| 5.30 < d ≤ 7.00 | ± 0.040 |

| 7.00 < d ≤ 9.00 | ± 0.045 |

| 9.00 < d ≤ 10.00 | ± 0.050 |

| 10.00 < d ≤ 11.00 | ± 0.070 |

| 11.00 < d ≤ 14.00 | ± 0.080 |

| 14.00 < d ≤ 18.00 | ± 0.090 |

| 18.00 < d ≤ 20.00 | ± 0.100 |

OVALITY

WHEN SUPPLIED IN RODS. Straightened wire:

| Nominal diameter d mm | Diameter tolerance a) mm | Supply capacity b) mm. | ||

| Lower tolerance | Higher tolerance | Minimum length | Maximum length | |

| 0.65 ≤ d < 0.80 | -0.010 | +0.022 | 50 | 2000 |

| 0.80 ≤ d < 1.01 | -0.015 | +0,030 | 30 | 2000 |

| 1.01 ≤ d < 1.35 | -0.020 | +0,040 | ||

| 1.35 ≤ d < 1.78 | -0.020 | +0,045 | ||

| 1.78 ≤ d < 2.01 | -0.025 | +0,055 | ||

| 2.01 ≤ d < 2.35 | -0.025 | +0,060 | 30 | 4000 |

| 2.35 ≤ d < 2.78 | -0.025 | +0,065 | ||

| 2.78 ≤ d < 3.01 | -0.030 | +0,075 | ||

| 3.01 ≤ d < 3.35 | -0.030 | +0,080 | 30 | 4000 |

| 3.35 ≤ d < 4.01 | -0.030 | +0,090 | ||

| 4.01 ≤ d < 4.35 | -0.035 | +0,100 | ||

| 4.35 ≤ d < 5.01 | -0.035 | +0,110 | 30 | 4350 |

| 5.01 ≤ d < 5.45 | -0.035 | +0,120 | ||

| 5.45 ≤ d < 6.01 | -0.040 | +0,130 | ||

| 6.01 ≤ d < 7.12 | -0.040 | +0.150 | 250 | 4350 |

| 7.12 ≤ d < 7.67 | -0.045 | +0,160 | ||

| 7.67 ≤ d < 9.01 | -0.045 | +0,180 | ||

| 9.01 ≤ d < 10.01 | -0.050 | +0,200 | ||

| 10.01 ≤ d < 10.50 | -0.070 | +0,240 | ||

a) Diameter tolerances of straightened and cut lengths according to EN 10270-1

b) Approximate data for information purposes.

STANDARD LENGTH TOLERANCES

| NOMINAL LENGTH | TOLERANCE |

| L < = 1000 mm. | +/- 1 mm. |

| 1000 < L < = 4000 | - 0mm. / +3 mm. |

Thanks to our wire rolling technology we are able to offer our customers the flat wire and square...

Thanks to our wire rolling technology we are able to offer our customers the flat wire and square...